By using the EOS oil water separator, businesses can meet the ISO 14001 requirement for environmental management system. The EOS Oil Water Separators are also approved by the German Institute (DIBT) for oil content in water after separation. Further, the EOS elements are made of PP fibre, which is a natural oil product.

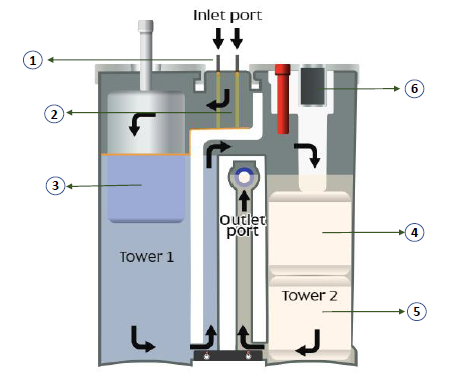

The element fibres of ELGi Oil Water Separators have been specially selected and treated to maximise adsorption. Separation elements have a multi-stage design, which increases filtration efficiency and allows easy serviceability. The elements are lightweight and packed in a bag that can be easily lifted and placed into the separation towers.

With the ELGi EOS oil water separator, you can avoid collecting the condensate. This eliminates the storage requirement of the hazardous condensate on site, which can be expensive and pose a health and safety risk. It also does not require costly disposal charges.

Unlike other oil-water separator designs where the whole unit needs to be replaced, only the separation elements of the EOS oil water separators need to be replaced after saturation. Replacing the entire unit every time can significantly harm the environment.

With the ELGi EOS oil water separator, you can avoid collecting the condensate. This eliminates the storage requirement of the hazardous condensate on site, which can be expensive and pose a health and safety risk. It also does not require costly disposal charges.

Unlike other oil-water separator designs where the whole unit needs to be replaced, only the separation elements of the EOS oil water separators need to be replaced after saturation. Replacing the entire unit every time can significantly harm the environment.

The EOS Oil Water Separators are gravity-operated and do not require electricity to function. The multi-inlet adapter also allows up to three condensate inlets into the same separator, thus eliminating the need for an additional equipment.